International Cleaning Week

Spotless Spaces Competition Finalist

Eppendorf Manufacturing

Sparkle Services Inc., BSC

Sparkle Services Inc. provides 24/7 cleaning and maintenance for the Eppendorf Manufacturing North American Headquarters, located at 175 Freshwater Blvd., Enfield, CT 06082. Spanning approximately 500,000 sq. ft., we have proudly served this facility for the past 20 years.

One of the key areas we manage is a white room for manufacturing, which operates around the clock. This space is ISO certified annually, and we have consistently passed certification without any negative observations regarding our responsibilities.

What specific measures do you or your team implement to ensure this space meets the highest standards of cleanliness and embodies the value of clean?

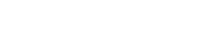

We are proud to showcase our dedicated training area, located within our facility. We believe we are the only commercial cleaning company in Connecticut with a dedicated training center, emphasizing the importance of exceptional training as the foundation of responsible cleaning. Our hands-on training uses working props and the Spartan Clean Check system. Once trained, our staff undergoes testing before transitioning to field training.

We utilize advanced cleaning equipment such as the Tennant T-16 and T600e EcH2O machines, ensuring environmentally friendly and effective cleaning.

To maintain high standards, certain ISO target tasks are met and signed off on daily, with Eppendorf staff conducting regular checks. Daily supervision and walkthrough inspections are carried out by the account supervisor, while monthly inspections are performed by our operations manager using Spartan Compuclean Software. Additionally, we conduct continuous reinforcement training four times a year to stay focused on procedures and goals.

The value is clear, both for our staff and the customer. We create an environment where our customer can continuously manufacture products without disruption. The cleanliness of the facility enhances work flow efficiency, ensuring the end product is produced without quality issues. Our staff takes great pride in their work, experiencing a true sense of ownership and satisfaction in contributing to this success.

How does cleaning this space contribute to the health and safety of those who use it?

We have been committed to green cleaning for many years, and in 2011, Hillyard Corp. honored us with an award recognizing our dedication to environmentally friendly practices. This achievement followed a thorough inspection of our facility, equipment, procedures, and training.

Our EcH2O equipment uses water only for cleaning, reflecting our commitment to sustainable practices. Our cleaning team is rigorously trained in techniques that prioritize efficiency and minimize waste—training is central to all our successes.

To maintain the highest standards of cleanliness, we follow strict protocols for this area. We use dedicated equipment specifically for this space to prevent any risk of cross-contamination. Additionally, we adhere to clear guidelines for the use of tools like microfibers, disposable dry mops, and wet mop changes, always prioritizing health and safety over appearance. Finally, ongoing inspections and continuous training are key to ensuring that these standards are met and maintained.

What does having a spotless space mean to you and your team?

We are truly honored to have achieved a spotless space that has instilled a deep sense of pride and ownership in our team. This sense of ownership is the driving force that motivates us to consistently uphold these high standards. Personally, there is no greater satisfaction than walking through this facility and seeing my staff smiling, knowing that our customers view us as friends, not just vendors. This accomplishment is a result of our unwavering commitment to both our team and our clients, fostering an environment where true teamwork thrives.